Precision casting is suitable for small and medium-sized products. Through this process, it is possible to cast fine parts and cast serial products.

Creamic shell casting

Bronze has always been one of the most popular materials in the making of metal statues.

The great civilizations of the ancient world depicted art in bronze from the introduction of the first sharp metal weapons onwards. The ‘Dancing Girl’ from Mohenjo Daro dates back to 2500 BC and is said to have been considered the world’s first bronze casting. The Greeks, however, were the first to cast man-sized bronze castings.

We can only guess how the bronze statue was made in those times. There remains some evidence that some kind of resin was used to make the statue, surrounded by a mixture of animal excrement and feces, put on fire, and waited for the resin to drain out. An alloy of tin and copper, which was supposed to be one of the first bronzes, was then poured into the dried mud masses.

That's how it all started. Of course, over the years, the technology of making bronze statues has changed all the time. The resin was slowly replaced by various waxes (initially beeswax, but now we use microcrystalline waxes with various additives), the mixture of mud and animal excrement was replaced by refractory materials (mixture of fireclay and gypsum), and ancient bronze was replaced by modern silicon bronzes.

The materials have changed, but the original idea of replacing wax with bronze remains the same.

Precision casting allows us to make an extremely accurate copy of the original, as we have replaced the refractory material with ceramics.

Why can we talk about precision, what is different now?

Following the classic procedure, a waxed copy of the original is poured into a mixture of brick meal, water and plaster.

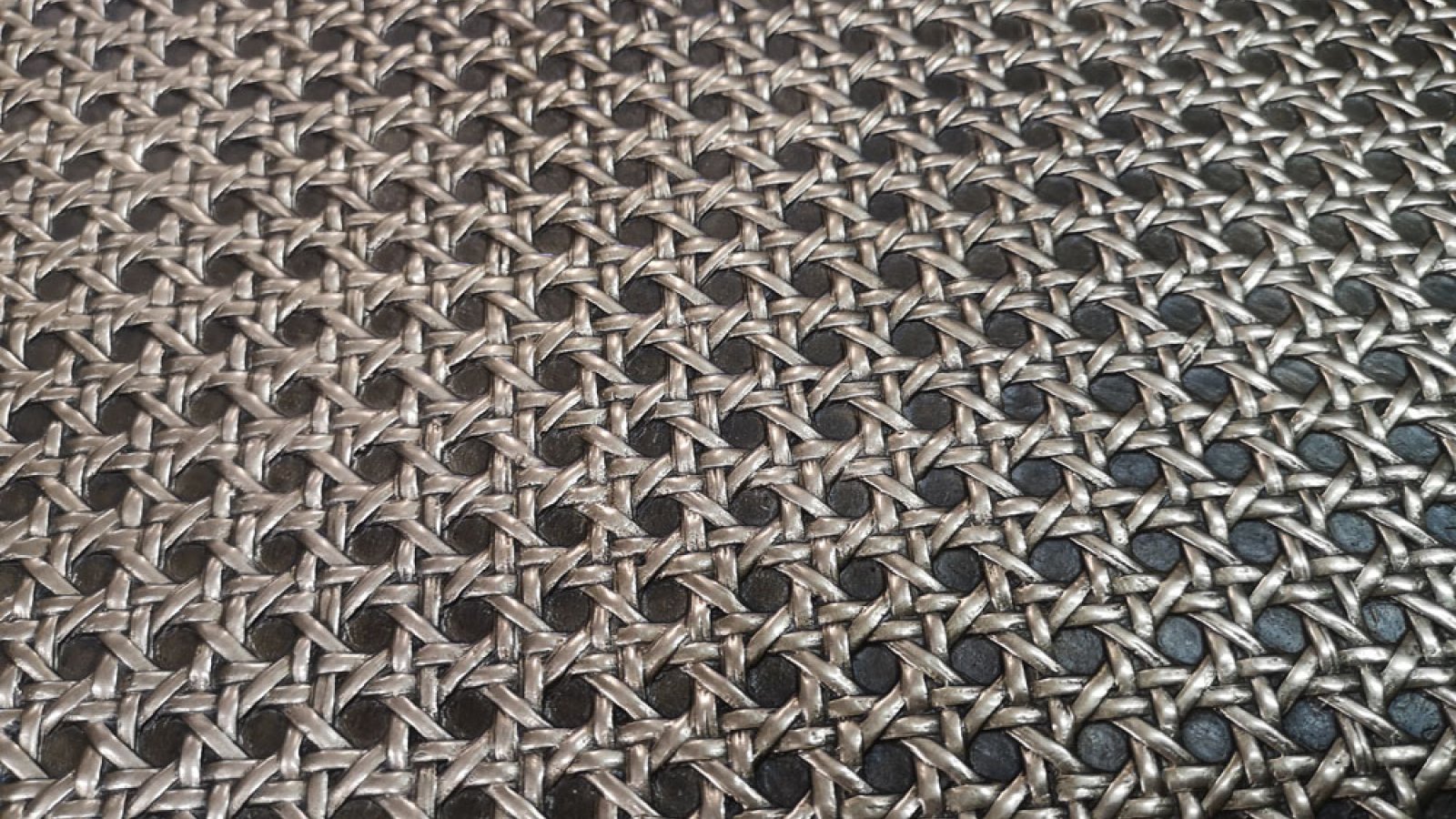

In the Cheramic shell process, the wax model is soaked in a special substance that coats every bit of wax. Blow off any bubbles and wait for the excess liquid to drain. Then apply loose ceramic sand to the coated wax. Repeat this process several times to obtain a crust about an inch thick. The wax is then removed from the mold, placed in an oven reaching 1100 ° C for 2 hours and the molds are ready for casting bronze.

When the bronze has cooled, break the ceramic shell with a hammer and get a precise casting.